Top Aluminum Composite Panel Manufacturers You Should Know?

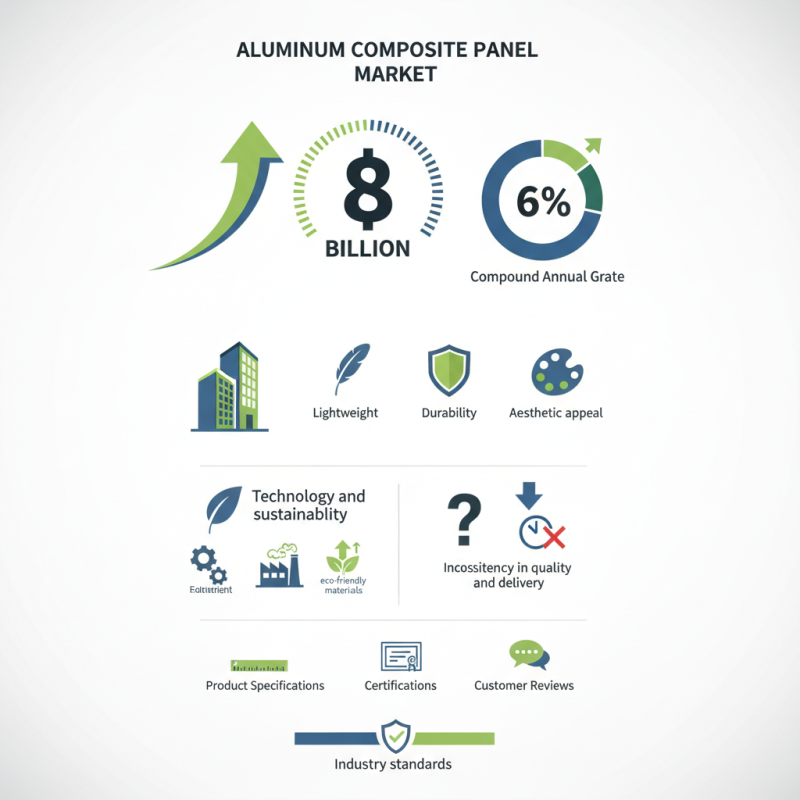

The global market for aluminum composite panels is rapidly evolving. As of 2023, it is projected to reach $8 billion, reflecting a compound annual growth rate of over 6%. This growth underlines the crucial role of aluminum composite panel manufacturers in architecture and construction sectors. These panels are known for their lightweight, durability, and aesthetic appeal.

Top manufacturers are making significant strides in technology and sustainability. Companies are investing in eco-friendly materials, enhancing performance while reducing environmental impact. However, not all manufacturers meet the growing demand for high-quality products. Some struggle with consistency in quality and delivery times. Choosing the right manufacturer is essential for successful projects.

Navigating the landscape of aluminum composite panel manufacturers can be challenging. It requires careful consideration of factors like product specifications, certifications, and customer reviews. Additionally, buyers should be aware of the industry standards that govern performance and safety. With the right information, customers can make informed decisions in this competitive market.

Overview of Aluminum Composite Panels and Their Applications

Aluminum composite panels (ACPs) are versatile materials made of two thin layers of aluminum enclosing a non-aluminum core. They offer durability and a stylish appearance. This combination provides resistance to weather, fire, and corrosion. Many industries utilize ACPs for various applications, including building facades, signage, and interior design.

The lightweight nature of ACPs makes them easy to handle and install. Architects appreciate their aesthetic flexibility. They can mimic natural materials like wood or stone while maintaining a modern look. However, not all designs and installations are flawless. Some projects face issues with long-term durability or environmental impact. It's essential to consider these factors during the design phase.

ACPs can also be tailored according to specific needs. They can incorporate different colors or finishes. Use in furniture design showcases their adaptability. Yet, misjudgment in choice may lead to unsatisfactory results. Understanding the material's properties is essential for successful application. As the industry evolves, ongoing reflection on usage and sustainability is needed.

Key Factors to Consider When Choosing a Manufacturer

When choosing an aluminum composite panel manufacturer, several key factors should be considered. First, evaluate the quality of materials. A significant percentage, nearly 40% of panel failures arise from subpar materials used in production. Rigid quality control measures ensure durability and safety. Check for compliance with international standards and certifications, which can indicate a reliable manufacturer.

Next, consider the manufacturer’s experience in the industry. Recent market studies show that companies with over ten years of experience tend to deliver more consistent quality products. Longevity often correlates with a better understanding of customer needs and market trends. It's also important to analyze their product range. A versatile portfolio can highlight a manufacturer's adaptability to different architectural designs and innovative solutions.

Cost is another essential factor. While cheaper options may seem appealing, they can lead to higher costs in the long run. Approximately 30% of buyers report regretting their choice due to unexpected failures needing replacement. It's vital to balance price with quality. Investing in a reputable manufacturer can save you from future headaches and financial losses. Making informed decisions here can significantly impact project outcomes.

Top Aluminum Composite Panel Manufacturers - Comparison of Key Factors

Top Global Manufacturers of Aluminum Composite Panels

Aluminum composite panels are essential in modern architecture. They offer durability, flexibility, and visual appeal. Notably, these panels are lightweight yet robust. Many manufacturers around the globe specialize in producing high-quality aluminum composite panels. These companies utilize advanced technology and sustainable practices to meet industry demands.

Different manufacturers focus on unique features. Some emphasize custom designs and finishes. Others might prioritize environmentally friendly materials. It’s crucial for buyers to evaluate quality and sustainability. However, not all products live up to expectations. There are instances where panels may not adhere properly or fade over time. Buyers must do thorough research.

Manufacturers often showcase innovative designs, but their implementation can be inconsistent. Questions arise about longevity and maintenance needs. Some clients may find the finished product does not match their vision. These experiences highlight the importance of clear communication with manufacturers. Evaluating a company’s track record is essential for success.

Innovative Technologies in Aluminum Composite Panel Production

The production of aluminum composite panels has evolved significantly. Innovative technologies have emerged to enhance quality, efficiency, and sustainability. These advancements help manufacturers meet the growing demand for eco-friendly construction materials.

Modern manufacturing processes often utilize advanced robotics. Automation streamlines production and reduces human error. This leads to consistent quality across large volumes. Additionally, 3D printing is becoming more common. It allows for custom designs that were previously hard to achieve.

Tips: Always check for certifications. This ensures the panels meet industry standards. Consider energy-efficient production methods. They can reduce costs and environmental impact.

While technology looks promising, challenges remain. Some firms may struggle with skill gaps in their workforce. Others might find it hard to invest in new technologies. Addressing these issues is crucial for long-term growth. By embracing innovation wisely, manufacturers can push the industry forward.

Market Trends and Future Directions for Aluminum Composite Panels

The aluminum composite panel (ACP) market is evolving rapidly. Architects and builders are increasingly drawn to these materials due to their outstanding versatility. Lightweight yet durable, ACPs can be used for exterior and interior applications. Their aesthetic appeal allows for innovative designs in modern architecture. Sustainability is another key factor, pushing more manufacturers to adopt eco-friendly materials.

Market trends indicate a growing demand for customized solutions. Clients seek panels that not only look great but also meet specific functionality requirements. However, there are challenges. Some manufacturers struggle to keep up with evolving design trends. This can lead to missed opportunities for innovation.

Focusing on future directions, manufacturers must embrace technology. Advanced manufacturing processes and digital designs are essential. Integration of smart features into ACPs is on the rise. While many are adapting, there are still gaps in quality control. Maintaining consistency remains a critical issue for the industry. Addressing these concerns will define the future of aluminum composite panels.