Essential Tips for Choosing Stainless Steel Wire Mesh?

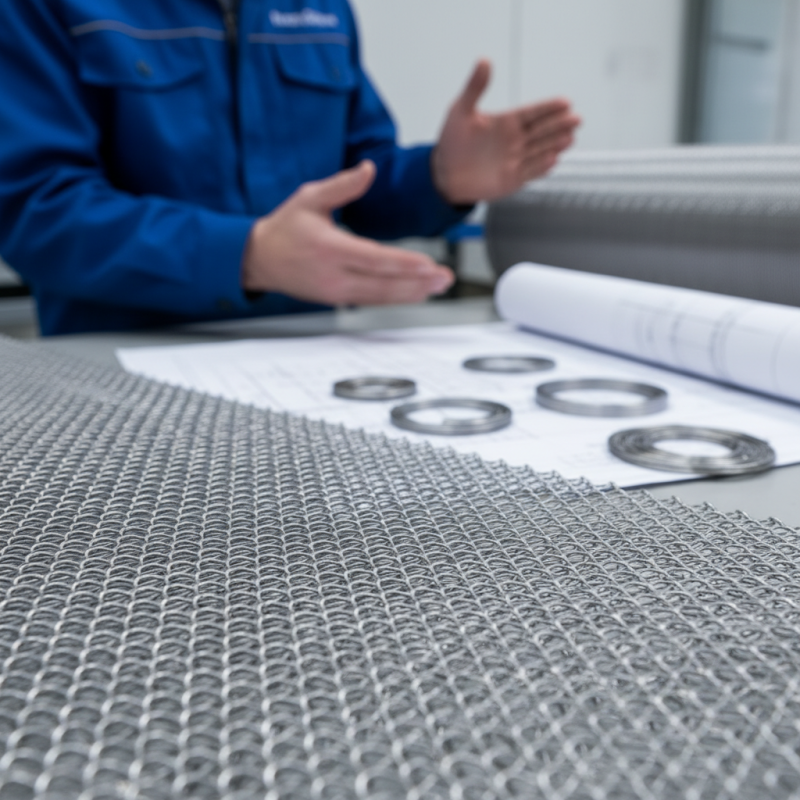

When it comes to selecting stainless steel wire mesh, expertise is invaluable. John Smith, a specialist in mesh manufacturing, emphasizes, "Choosing the right stainless steel wire mesh is crucial for your project’s success." This highlights the importance of informed decisions in the industrial applications of this material.

stainless steel wire mesh offers durability and resistance to corrosion. However, not all mesh types are created equal. Understanding different grades and specifications is essential. For instance, 304 and 316 grades serve various environmental conditions. It’s easy to overlook some details in the selection process. Yet, the right choice can significantly impact your project's performance.

Take time to assess your specific needs. Factors like the mesh size and wire diameter matter greatly. Even a small error in these choices can lead to issues later. Reflecting on these points will ensure a better outcome. Prioritizing quality over cost is crucial in the long run.

Understanding the Different Types of Stainless Steel Wire Mesh

When considering stainless steel wire mesh, understanding its various types is vital. Different grades and weave patterns cater to specific needs. For instance, 304 stainless steel mesh is widely used due to its balance of corrosion resistance and strength. In contrast, 316 stainless steel offers superior protection against corrosion, especially in marine environments. Studies indicate that 316 stainless steel exhibits a 20% increase in durability when exposed to saline solutions.

The weave type also impacts the mesh's performance. Plain weave provides uniform open areas, while twill weave enhances flexibility and strength. According to industry reports, twill weave meshes are 30% stronger than plain weave meshes of the same diameter. However, one must consider that the increased strength can lead to higher costs.

Decisions in selecting the right mesh involve trade-offs. Higher-grade materials demand a greater investment but may save costs in maintenance over time. In some cases, users overlook mesh size, leading to inefficiencies. It’s important to ensure the chosen mesh size matches project requirements. Attention to detail is crucial in preventing future complications.

Key Factors to Consider When Choosing Stainless Steel Wire Mesh

Choosing the right stainless steel wire mesh involves several key factors. Firstly, consider the grade of stainless steel. Different grades have varying corrosion resistance and strength. For example, 304 stainless steel is commonly used due to its balance of cost and performance. Yet, in more corrosive environments, 316 stainless steel might be necessary. This choice can directly impact the mesh's lifespan.

Another important aspect is the mesh’s opening size. Smaller openings provide finer filtration, while larger openings allow for better air or water flow. Think about the application. Is it for architectural design or industrial use? Each purpose demands different specifications. Furthermore, adjusting one factor can affect the overall performance. It’s worth noting that choosing a size impulsively could lead to inefficiencies later on.

While these factors are vital, it’s easy to overlook the importance of wire diameter. Thicker wires add durability but may restrict flow. Balancing these elements requires careful thought. Sometimes, testing a few options before finalizing your decision can help. Mistakes can happen, like selecting the wrong mesh for a specific task. It's crucial to learn from those experiences to improve future choices.

Essential Tips for Choosing Stainless Steel Wire Mesh

| Dimension | Wire Diameter (mm) | Aperture Size (mm) | Mesh Count (per inch) | Material Grade | Application |

|---|---|---|---|---|---|

| 30 x 30 cm | 0.8 | 2.0 | 14 | 304 | Filtration |

| 50 x 50 cm | 1.0 | 3.0 | 10 | 316 | Construction |

| 40 x 40 cm | 1.5 | 4.0 | 8 | 304 | Animal Enclosures |

| 60 x 60 cm | 2.0 | 5.0 | 6 | 316 | Food Processing |

| 20 x 20 cm | 0.5 | 1.5 | 20 | 304 | Decorative |

Analyzing the Wire Diameter and Mesh Opening Size

When choosing stainless steel wire mesh, wire diameter and mesh opening size are critical factors. The wire diameter significantly affects the mesh's strength and durability. According to industry standards, a thicker wire offers enhanced resistance to bending and deformation. This means structures built with thicker wires can handle heavier loads, but choosing the right diameter is sometimes tricky. Reports show that a wire diameter of 0.08 inches (or 2 mm) is commonly favored for industrial applications, striking a balance between flexibility and strength.

Mesh opening size also plays a vital role in determining functionality. Smaller openings offer finer filtration but may restrict airflow. On the contrary, larger openings allow for better ventilation but can compromise filtration efficiency. A recent survey indicated that mesh sizes between 1/8 inch and 1/4 inch are optimal for various applications, including agriculture and construction. However, choosing these sizes can lead to potential issues such as clogging if not properly maintained. It's essential to consider the specific needs of your project before making a decision. Balancing these factors can lead to better performance but may require ongoing adjustments.

Evaluating Corrosion Resistance and Strength Quality

When selecting stainless steel wire mesh, evaluating corrosion resistance and strength quality is crucial. Corrosion can occur in various environments. High humidity, exposure to salt, or chemicals can weaken the material. Look for mesh with enhanced corrosion resistance properties. This can ensure longevity and durability in demanding conditions.

Strength is another essential factor. The wire gauge and weave pattern affect the mesh's overall strength. Thicker wires often provide better support. Meanwhile, a tighter weave can improve resistance to deformation. However, thicker mesh may limit visibility. This trade-off requires careful consideration based on your specific project needs.

It's important to reflect on the balance between quality and requirements. Not all projects will need high-strength mesh. Sometimes, less robust options could suit your needs just as well. Assess your environment carefully before making a decision. This could save time and cost in the long run.

Comparing Cost and Manufacturer Reputation for Wire Mesh Options

When choosing stainless steel wire mesh, cost and manufacturer reputation are vital factors. Research shows that quality often correlates with price. A recent industry report highlighted that lower-cost options can lead to issues like corrosion resistance. In fact, some budget mesh may only contain 304-grade stainless steel. This grade lacks the durability of its 316 counterpart. Thus, investing in quality can save money in the long term.

Reputation matters too. Companies with a strong track record often provide better warranties and customer support. For example, data indicates that top-rated manufacturers have a 30% lower return rate. Their products also undergo more rigorous testing. This ensures that the wire mesh meets rigorous industry standards. Reviews and testimonials reveal that buyers prefer reputable manufacturers over cheaper options. Yet, not all well-known brands guarantee excellence. Some may compromise quality to meet demand.

Understanding these nuances is crucial. High price tags don’t always reflect superior products. It’s essential to read specifications and verify manufacturer claims. Seek certifications or industry standards before making a purchase. Balancing cost and reputation can be challenging, but informed choices lead to better outcomes.

Comparison of Stainless Steel Wire Mesh Options

This chart displays the cost per square meter for different grades of stainless steel wire mesh. Grade 316 is the most expensive due to its corrosion resistance, while Grade 430 is the most affordable. When choosing wire mesh, it's essential to consider both the cost and the manufacturer reputation to ensure quality and durability.