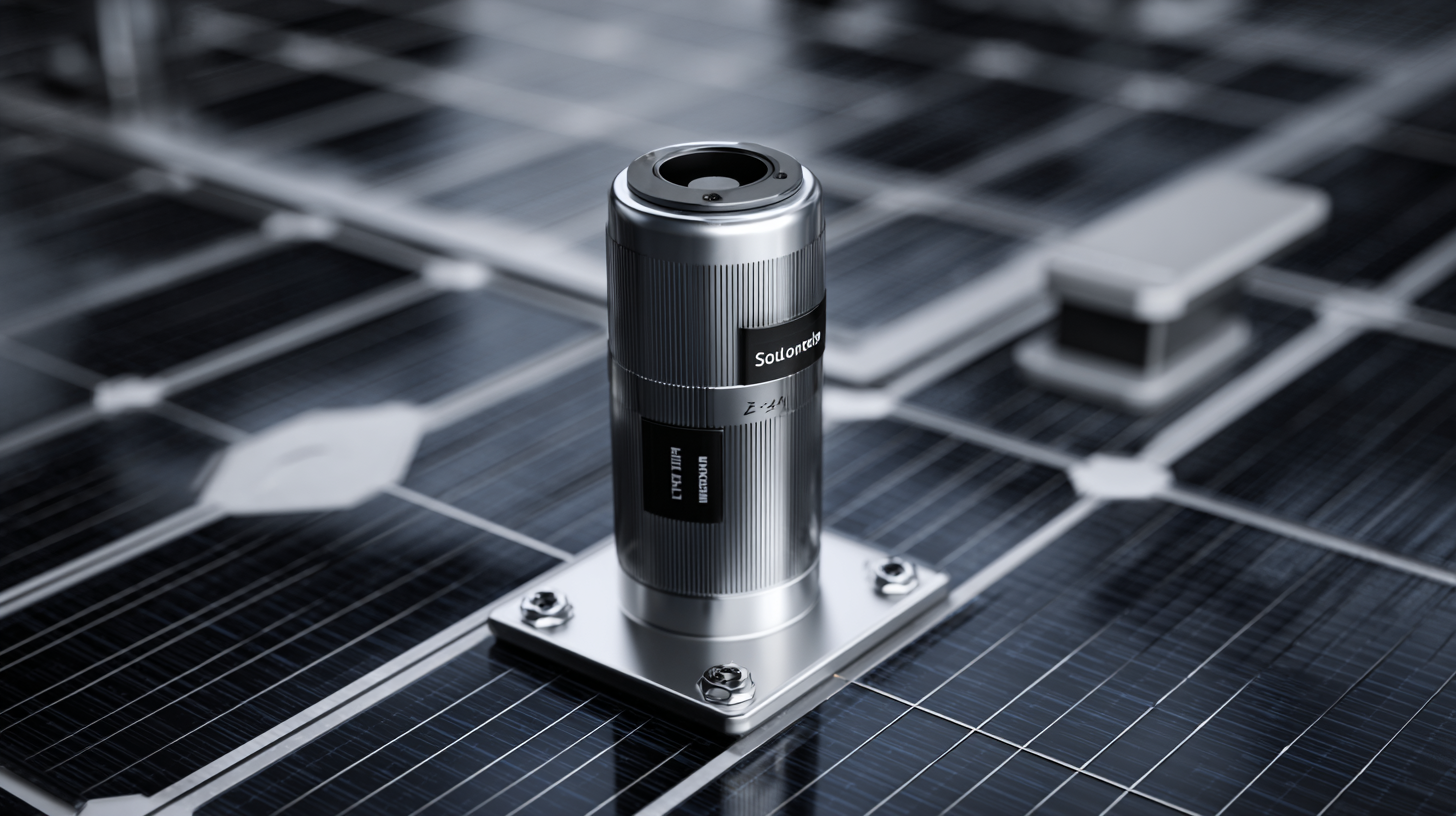

Unparalleled Solar Connector Solutions Crafted in China for a Global Market

In today's rapidly evolving renewable energy landscape, the demand for efficient and reliable solar systems has never been greater. At the heart of these advancements lies the Solar Connector—a small but crucial component that ensures the seamless integration of solar panels to energy systems.  Crafted in China, these connectors have gained a reputation for their unparalleled quality and innovative design, positioning them as a favored choice in the global market. This blog explores the myriad reasons why Chinese-manufactured Solar Connectors stand out, including their exceptional durability, versatility in various environmental conditions, and cutting-edge technology that enhances energy transfer efficiency. As we delve into the factors contributing to their growing popularity, it becomes evident why these Solar Connectors are transforming the way we harness solar energy across the globe.

Crafted in China, these connectors have gained a reputation for their unparalleled quality and innovative design, positioning them as a favored choice in the global market. This blog explores the myriad reasons why Chinese-manufactured Solar Connectors stand out, including their exceptional durability, versatility in various environmental conditions, and cutting-edge technology that enhances energy transfer efficiency. As we delve into the factors contributing to their growing popularity, it becomes evident why these Solar Connectors are transforming the way we harness solar energy across the globe.

Overview of Solar Connector Technologies and Their Role in Renewable Energy

Solar connectors play a pivotal role in the efficiency and reliability of solar energy systems. As the market for renewable energy continues to grow, the demand for high-quality solar connectors has also surged. These components are essential for ensuring safe and effective connections between solar panels and inverters, thus optimizing energy transfer and minimizing losses.

With advancements in technology, manufacturers are now offering innovative solutions that enhance performance and durability, catering to diverse installation environments across the globe.

Tips for selecting the right solar connectors include ensuring compatibility with your solar panels and inverters to avoid potential functionality issues. It's also important to consider the environmental conditions of the installation site; connectors must be resistant to UV exposure, humidity, and extreme temperatures to guarantee longevity. Additionally, opting for connectors with proven track records in energy efficiency can lead to better overall system performance and reduced operational costs.

As nations prioritize their renewable energy transitions, investing in high-quality solar connector technology becomes increasingly critical. Emerging innovations and collaborations among leading companies are paving the way for enhanced functionality and sustainability. By focusing on these advancements, the solar industry can continue to expand its reach, promoting cleaner energy solutions worldwide.

Key Features of Different Solar Connector Types for Efficient Energy Transmission

In the rapidly evolving field of solar energy, selecting the right connector is crucial for maximizing efficiency and ensuring durability in energy transmission. There are various types of solar connectors available, each designed with specific features to cater to different installation needs. For instance, MC4 connectors are widely recognized for their reliability and ease of use, making them a go-to choice for many solar projects. Their secure locking mechanism ensures a stable connection, reducing the risk of disconnections caused by environmental factors.

When considering solar connectors, it's important to assess the voltage and current levels they can handle. Connectors like Tyco Solar Connectors offer high-current capabilities, making them suitable for larger installations where enhanced performance is necessary. Additionally, their weather-resistant properties ensure longevity even in harsh outdoor conditions.

Tip: Always check for compatibility between different connector types before combining them in a system.

Furthermore, investing in connectors that comply with international standards guarantees safety and performance in various global regions. Some connectors are designed with quick-connect features, enabling faster installations, which can significantly reduce labor costs.

Tip: Opt for connectors with color-coded designs to simplify the installation process and avoid confusion during system setup.

Market Demand Analysis: Growth Projections for Solar Connectors Through 2025

The solar energy sector continues to witness unprecedented growth, driven by escalating global demand for renewable energy solutions. As the world moves towards sustainable energy practices, the significance of efficient solar connectors cannot be overstated. Market studies project a robust expansion in the solar connector market, with an estimated growth rate pushing towards new heights through 2025. This surge is influenced by advancements in solar technology, increasing investments in green infrastructure, and heightened consumer awareness regarding the benefits of solar power.

China has emerged as a pivotal player in the manufacturing of solar connectors, leveraging its advanced production capabilities and cost-effective solutions. As international markets seek reliable and advanced products, Chinese manufacturers are innovating to cater to the diverse requirements of global clients. The expectation is that, by 2025, solar connectors will not only serve as crucial components in photovoltaic systems but also drive overall efficiency and installation convenience. This evolution presents lucrative opportunities for manufacturers and distributors alike, positioning them for success in a rapidly changing energy landscape.

Projected Growth of Solar Connector Market (2023-2025)

This chart illustrates the projected market growth for solar connectors from 2023 to 2025, showing a consistent increase in demand driven by the global push for renewable energy solutions.

Comparison of Chinese Manufacturing Standards vs. Global Market Requirements

The current dynamics of the solar connector industry highlight the crucial differences between Chinese manufacturing standards and global market requirements. Chinese manufacturers have made significant strides in improving quality control and aligning output with international standards, yet skepticism remains among global consumers regarding product reliability. A recent report indicated that approximately 60% of foreign consumers still associate "Made in China" with lower quality, despite innovations in manufacturing techniques and adherence to environmental regulations.

As the Chinese government prioritizes domestic products through policies like preferential treatment in government procurement, there is an increasing push for enhanced compliance with international standards. Data suggest that the solar connector market is expected to grow to $3.1 billion by 2027, largely driven by the rise in renewable energy installations worldwide. For China to capitalize on this growth, aligning manufacturing standards with global requirements is essential. According to industry analysts, companies that can demonstrate adherence to international certifications will likely gain a competitive edge, reflecting a shift from cost-based competition to quality-driven differentiation.

In an increasingly competitive global landscape, the transition towards high-quality production is vital for Chinese manufacturers of solar connectors. Emphasizing precision engineering and durability not only meets the evolving expectations of international clients but also combats prevalent perceptions of inferiority. This evolution is imperative as China navigates ongoing trade tensions and seeks to solidify its position in the renewable energy sector.

Innovative Developments in Solar Connectors: Trends Shaping the Future

As the solar energy sector continues to evolve, innovative developments in solar connectors are playing a significant role in shaping the future of this industry. According to a recent report by Market Research Future, the global solar connector market is projected to reach $934 million by 2025, growing at a compound annual growth rate (CAGR) of 14%. This growth is largely driven by advancements in connector design, materials, and manufacturing processes, which enhance efficiency and reliability in solar power systems.

One notable trend is the push towards higher power ratings in solar connectors, with more modules designed to handle greater electrical output. Companies in China are at the forefront of this transformation, creating connectors that can withstand harsh environmental conditions while ensuring optimal performance. Additionally, the integration of smart technology into solar connectors is becoming increasingly popular, allowing for real-time monitoring and maintenance, thereby increasing system longevity and efficiency.

Tip: When selecting solar connectors, consider options that offer higher IP ratings for better protection against dust and moisture. Similarly, look for connectors that boast easy installation features to save time and reduce labor costs. As the market progresses, staying informed about the latest innovations will help businesses make strategic decisions in solar project planning.

Unparalleled Solar Connector Solutions Crafted in China for a Global Market - Innovative Developments in Solar Connectors: Trends Shaping the Future

| Connector Type | Current Rating (A) | Operating Voltage (V) | Temperature Range (°C) | Material | Market Trends |

|---|---|---|---|---|---|

| MC4 Connector | 30 | 1000 | -40 to +85 | PC/PA | Rising Adoption in Residential Systems |

| H4 Connector | 40 | 1500 | -40 to +90 | TPE | Growing Trend in Utility-Scale Projects |

| Bristol Connector | 25 | 600 | -40 to +75 | PE | Focus on Lightweight Solutions |

| SMA Connector | 50 | 1200 | -40 to +85 | Brass, Gold Plated | Emerging Use in Smart Grid Integration |