Why is a Laboratory Sample Pulverizer Essential for Your Analysis?

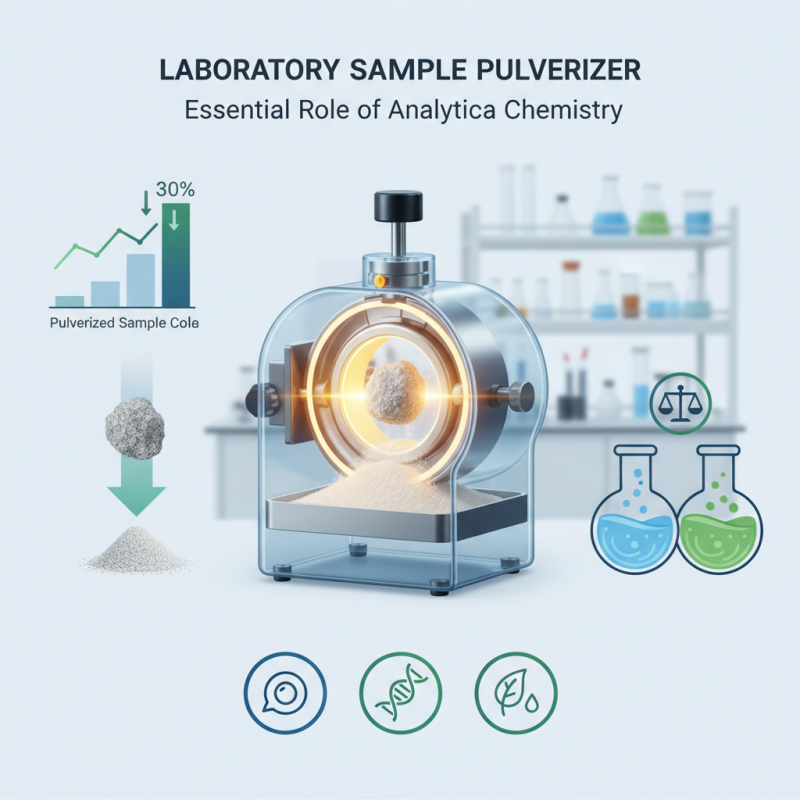

In the realm of analytical chemistry, precision is key. A laboratory sample pulverizer is essential for obtaining accurate results. This device ensures that samples are ground uniformly, allowing for better consistency in analysis. According to a recent report from the International Journal of Analytical Sciences, samples that are not pulverized properly can lead to a 30% deviation in results. This highlights the significance of using an effective pulverizer.

Dr. Emily Chen, a leading expert in laboratory equipment, emphasizes, “The right pulverizer can make a world of difference in analytical results.” Her insights underscore the importance of selecting a quality laboratory sample pulverizer. Many labs overlook this essential tool, leading to questionable outcomes. This oversight can be detrimental in fields like pharmaceuticals and environmental testing.

Despite advancements in technology, not all pulverizers meet the highest standards. Some models produce inconsistent particle sizes, which can compromise analysis. Laboratories must carefully evaluate the options available. Investing in a high-quality laboratory sample pulverizer is crucial for ensuring reliability and accuracy in research.

Understanding the Role of Laboratory Sample Pulverizers in Material Analysis

Laboratory sample pulverizers play a crucial role in material analysis. They are designed to crush, grind, and homogenize samples. This process helps ensure that the material can be accurately analyzed. Without proper pulverization, the results can be skewed or misleading.

A well-pulverized sample allows for even distribution of particles. This uniformity is essential for tests like chemical analysis or mineralogy. Researchers need consistent samples to make valid comparisons. If the sample isn’t properly prepared, the entire analysis might need to be redone. It’s frustrating and a waste of time.

Choosing the right pulverizer can be challenging. Different materials require different methods. Sometimes, the equipment may not perform as expected. This can lead to large discrepancies in results. Careful consideration and testing are necessary. Adjusting parameters might be required to find the optimal setting for each type of sample. This reflects a layer of complexity in the analysis process.

Key Benefits of Using a Pulverizer for Homogeneous Sample Preparation

A laboratory sample pulverizer plays a crucial role in sample preparation. It ensures that materials are finely ground and consistent. When samples are homogeneously prepared, analysis becomes much more reliable. Inconsistent particle sizes can lead to varied results. This highlights the need for uniformity in the preparation stage.

Using a pulverizer offers several key benefits. It helps achieve a consistent granule size, which is vital for accurate measurements. For instance, a sample with all particles the same size can enhance the precision of an analysis. This ultimately leads to better, more reproducible results. However, one must also consider the choice of pulverizing techniques. Not every method is suitable for all materials. Experimentation may be necessary.

While pulverizers are efficient, they also require proper usage. Overloading a pulverizer can lead to uneven results. Cleanliness matters too; contamination can compromise a sample's integrity. Each step of the sample preparation process is important, yet sometimes overlooked. Reflection on these aspects is essential for achieving optimal results in laboratory analyses.

Industry Standards: Particle Size Reduction Requirements in Laboratories

In the realm of laboratory analysis, particle size reduction is a crucial step. It directly impacts the accuracy and reliability of results. Consistent particle size improves the homogeneity of samples. This is essential for various tests, such as chemical assays or material characterization.

Laboratories must adhere to industry standards for particle size. Different materials require specific particle sizes to ensure optimal performance in experiments. For example, finer particles may enhance reactivity in chemical reactions. However, achieving the precise size can be challenging. Some methods may introduce variability or contamination.

Analyzing the effectiveness of different pulverizing methods can reveal strengths and weaknesses. Techniques such as ball milling or jet milling each have their pros and cons. Yet, many laboratories encounter obstacles during implementation. Time constraints and budget limitations can impact the choice of equipment. Reflection on these challenges can lead to improvements in procedures.

Why is a Laboratory Sample Pulverizer Essential for Your Analysis?

| Parameter | Requirement | Standard | Notes |

|---|---|---|---|

| Particle Size | < 75 µm | ISO 13320:2009 | Critical for accuracy in analysis |

| Homogeneity | ≥ 95% | ASTM D6913 | Ensures consistent results |

| Sample Loss | < 5% | Internal Standard | Minimize waste of expensive samples |

| Processing Time | ≤ 5 min per sample | Efficiency Standard | Faster turnaround for analysis |

| Durability | Lifetime > 500 cycles | Manufacturer Specifications | Reduced need for maintenance |

Comparative Analysis of Pulverization Methods and Their Applications

Pulverization methods vary significantly in their application and effectiveness. Each technique has its unique strengths and weaknesses. For instance, mechanical pulverization is commonly used in labs for its efficiency. It reduces samples quickly, but may generate heat, which can affect sample integrity. Studies suggest that up to 15% of certain materials may lose their properties when exposed to excessive heat.

On the other hand, cryogenic pulverization preserves the physical and chemical properties of samples better than mechanical methods. By using liquid nitrogen, this method prevents thermal degradation. However, it requires specialized equipment and careful handling. Reports indicate that cryogenic methods can maintain up to 95% of the original material's properties. This makes it preferred for sensitive materials, such as proteins and enzymes, where maintaining structure is critical.

Choosing the right method is not always straightforward. For example, a lab may opt for a method based on speed rather than accuracy. This could lead to unreliable results. As methods evolve, it's essential to continually assess their effectiveness and applicability. Regular evaluation helps in identifying limitations and improving sampling strategies.

Case Studies: Impact of Sample Preparation on Analytical Results

Sample preparation plays a critical role in analytical chemistry. A laboratory sample pulverizer simplifies this process. It allows for uniform particle sizes, which are essential for accurate results. Different materials require specific reduction techniques to achieve this uniformity. When samples are not prepared properly, analytical errors can occur.

Consider a case where mineral samples were analyzed. The pulverization process was inconsistent. Some particles remained coarse, affecting the overall analysis. The results showed discrepancies, leading to misinterpretations. Without adequate sample preparation, even sophisticated analytical instruments can yield flawed data.

In another instance, soil samples showed variations in nutrient content due to uneven grinding. Operators noticed the significant differences in results. This prompted a review of the preparation methods. Reflecting on these situations reveals the importance of refinement. Effective sample preparation can drastically improve the reliability of analytical outcomes. A minor oversight in this phase can lead to larger implications down the line.