2026 Best Sealed Battery Options for Reliability and Performance?

Sealed batteries have become vital in various applications, from consumer electronics to renewable energy systems. According to a study by ResearchAndMarkets, the global sealed battery market is projected to reach $22 billion by 2026, driven by increasing demands for reliability and performance. These batteries offer a sealed design that minimizes leakage risks and lowers maintenance needs.

Recent advancements highlight the need for comprehensive evaluations. Different sealed battery technologies, like AGM and gel, exhibit unique strengths and weaknesses. For instance, while AGM batteries excel in rapid discharge capabilities, gel batteries shine in deep cycle performance. Choosing the right sealed battery involves understanding these distinctions. This ensures optimal application-specific performance while maintaining cost-effectiveness.

Despite their advantages, sealed batteries are not without challenges. They can be more expensive than traditional options. Some models face issues with temperature sensitivity, impacting longevity. As technology progresses, manufacturers must continuously innovate to improve sealed battery designs. Understanding these factors will guide consumers toward the best options.

Overview of Sealed Battery Types and Their Applications

Sealed batteries come in various types, each designed for specific applications. Common varieties include

lead-acid, lithium-ion, and nickel-metal hydride. The choice depends on

factors like usage, size, and energy needs. Lead-acid batteries are known for their reliability

in automotive settings. They are durable and relatively inexpensive. However, they can be heavy and may require maintenance.

Lithium-ion batteries offer high energy density. They are lighter and often found in portable electronics.

These batteries charge quickly but may sometimes face issues with longevity. A key consideration is

temperature; extreme heat can degrade their performance.

Tips:

Ensure proper ventilation

for your battery systems. This will prevent overheating and enhance lifespan. Regularly check for signs of wear

or leakage. Always follow safety guidelines when handling batteries. Your awareness can help avoid accidents.

Evaluate your needs carefully before selecting a battery type. The best choice hinges on understanding your

specific performance requirements.

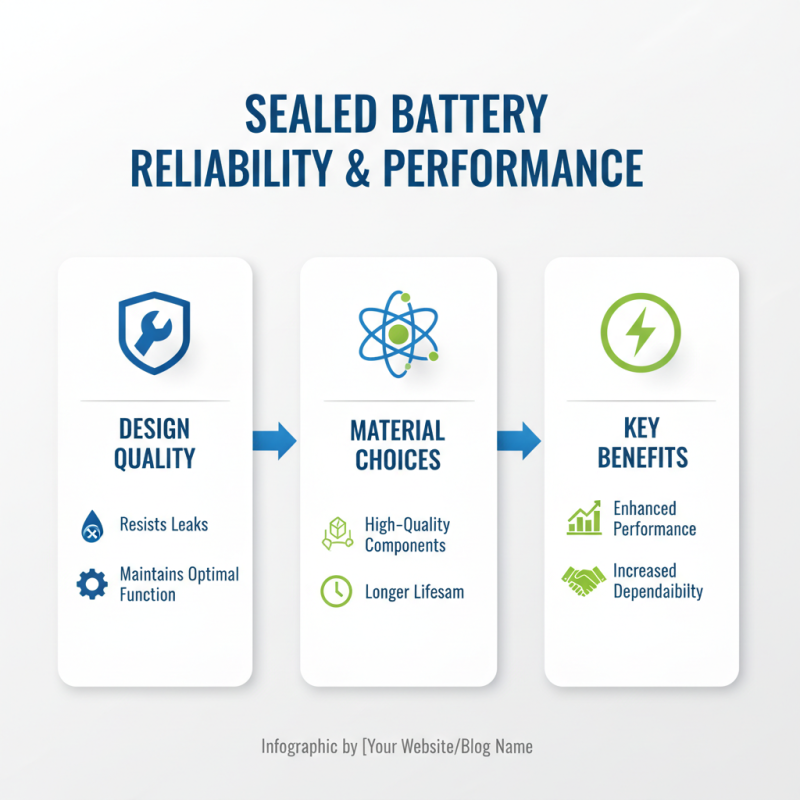

Factors Influencing Reliability in Sealed Battery Design

When it comes to sealed batteries, reliability and performance are critical. Several factors influence how well these batteries function. Design quality is essential. A well-constructed battery can resist leaks and maintain optimal performance. Material choices also play a key role. High-quality materials lead to better performance and longer lifespan.

Thermal management is another significant factor. Batteries generate heat during use. If not managed correctly, this can lead to reduced efficiency. Effective thermal solutions can extend the battery's life. Users should pay attention to how their batteries manage heat. Some batteries perform well initially but degrade quickly under heat stress.

**Tips:** Choose batteries with robust enclosures. This can prevent physical damage. Check for user reviews focused on longevity. It's a good way to gauge reliability. Remember, no battery is perfect. It’s wise to monitor performance regularly.

Performance Metrics to Consider for Sealed Batteries

When selecting sealed batteries, performance metrics matter. One critical aspect is energy density. According to industry reports, higher energy density leads to longer runtimes. Batteries with 200 Wh/kg offer a significant advantage. This density allows devices to operate longer between charges. However, not all applications require such high energy. Sometimes, lower density options suffice.

Another key metric is cycle life. Quality sealed batteries typically last between 500 to 1000 cycles. This longevity ensures reliability over time. A battery with a shorter cycle life may need more frequent replacements. This can translate to higher costs. Monitoring usage patterns can help in selecting the right battery type.

Temperature tolerance is also vital. Many batteries perform poorly in extreme conditions. For instance, some can lose efficacy when exposed to high heat. Data indicates that a 10°C increase can reduce capacity by 5-10%. It’s crucial to consider the environment in which the battery will operate. Balancing these metrics requires thoughtful evaluation. Battery choice should align with both performance and reliability requirements.

2026 Best Sealed Battery Options for Reliability and Performance

| Battery Type | Capacity (Ah) | Voltage (V) | Weight (kg) | Cycle Life (Cycles) | Max Discharge Rate (C) |

|---|---|---|---|---|---|

| Lead Acid | 100 | 12 | 30 | 500 | 1.5 |

| AGM | 120 | 12 | 35 | 800 | 2 |

| Lithium-ion | 150 | 12 | 25 | 2000 | 3 |

| Gel | 85 | 12 | 28 | 400 | 1.2 |

| Nickel-Cadmium | 70 | 12 | 40 | 1500 | 1.0 |

Top Brands and Models of Sealed Batteries for 2026

As we look forward to 2026, choosing the right sealed battery becomes crucial for both reliability and performance. Recent industry reports indicate that sealed batteries have shown a significant growth in demand, with the market forecast to reach $14 billion by 2026. This surge underscores the importance of selecting models that not only support high energy needs but also deliver consistent performance.

Several top contenders are standing out in the sealed battery landscape. These batteries are designed with advanced materials that enhance durability and charge cycles. For example, options featuring AGM technology are popular for their ability to withstand vibrations and extreme temperatures. However, it's worth noting that not all models meet expectations in longevity and efficiency. Reports suggest that while some batteries claim a lifespan of up to 10 years, real-world usage often falls below that threshold.

Several reputable models also emphasize fast charging times and low self-discharge rates. However, users often encounter variances in performance based on environmental conditions and maintenance. It's essential to consider whether the battery can sustain optimal performance in varying temperatures. This inconsistency raises questions about reliability that potential buyers should reflect on before making a choice. Choosing the right sealed battery involves careful consideration of specifications and personal requirements.

2026 Sealed Battery Performance Comparison

Future Trends in Sealed Battery Technology and Development

Sealed batteries are evolving rapidly. Many experts predict that solid-state batteries will dominate the market by 2026. These batteries offer improved energy density and safety. Current liquid electrolyte batteries often face risks of

leakage and overheating. In contrast, solid-state designs can reduce these safety issues significantly. According to industry reports, solid-state batteries could achieve an energy density of over 500 Wh/kg. This is a game changer.

Manufacturers are also exploring new materials like lithium-sulfur. Lithium-sulfur batteries promise lower costs and higher capacities. Yet, they come with challenges. Their cycle life is not as robust as traditional lithium-ion options. Researchers are working to address this issue. The race is on to find ways to enhance longevity and reliability.

Sustainability is another trend gaining traction. Recycling processes for sealed batteries are improving. Nearly 95% of materials can potentially be recovered. However, still, many recycling programs aren't fully established. The industry needs to work together. Advancements in both technology and recycling practices will propel sealed batteries forward.

Related Posts

-

Exploring the Benefits and Applications of Sealed Lead Acid Batteries in Modern Technology

-

The Ultimate Guide to the 10 Best SLA Batteries for Your Needs

-

Unlocking the Future of Energy Storage Innovations with 12 Battery at the 2025 China Import and Export Fair

-

How to Choose the Right Lawnmower Batteries for Your Needs?

-

Why Batteries Delivered Directly to Your Door Are Essential for Convenience

-

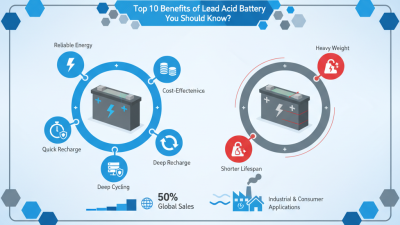

Top 10 Benefits of Lead Acid Battery You Should Know?