5 Reasons Why the Best Cam Switch Is Essential for Your Industrial Needs

In the ever-evolving landscape of industrial automation, choosing the right control components can significantly impact operational efficiency and safety. Among these crucial components, the cam switch stands out as a vital element for many industries. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach $295.65 billion by 2025, with a significant portion driven by the integration of reliable and versatile control switches like cam switches. These devices allow for precise control over machinery and processes, ensuring seamless operation in manufacturing, energy, and other sectors. With the increasing demand for automated solutions, understanding the essential role of cam switches becomes imperative for businesses looking to optimize their performance and reliability. In this blog, we will delve into five compelling reasons why investing in the best cam switch is fundamental to meet your industrial needs.

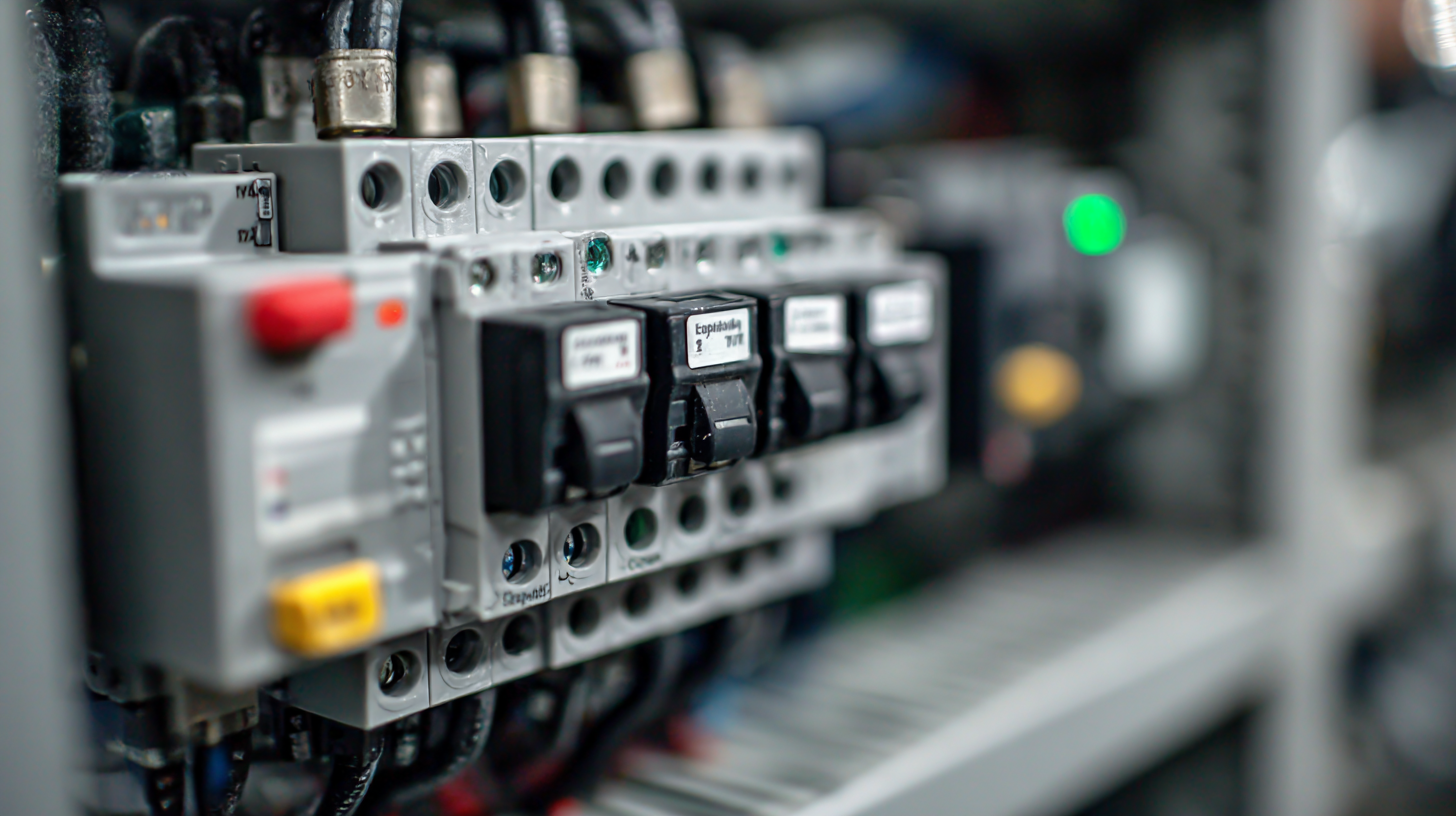

Advantages of Using Cam Switches Over Traditional Switches in Industry

In the industrial sector, the choice of switches can significantly impact operational efficiency and safety. Cam switches offer distinct advantages over traditional switches, making them an essential component in various applications. One key benefit is their robust design, which can handle higher currents and voltages compared to conventional alternatives. This durability ensures reliable operation in demanding environments, reducing the need for frequent replacements and maintenance.

Additionally, cam switches provide precise control over electrical circuits. Unlike traditional switches, which may have a binary on-off function, cam switches can be configured to multiple positions, allowing users to select specific functions seamlessly. This versatility is particularly useful in complex machinery where varied settings are necessary for different operations. Furthermore, their ability to provide clear visual indicators of the current position enhances safety, enabling operators to quickly assess the status of equipment at a glance. Overall, the reliability, versatility, and safety features of cam switches make them a superior choice for industrial applications.

Key Features to Look for in a High-Quality Cam Switch

When choosing a cam switch for industrial applications, it's essential to consider key features that ensure reliability and efficiency. One of the most critical factors is durability; high-quality cam switches are often designed to withstand harsh environments, making them ideal for industrial settings. Look for switches with robust materials that can resist dust, moisture, and temperature fluctuations. This durability extends the lifespan of the equipment and minimizes downtime, which is crucial in any industrial operation.

Another important feature to consider is the ease of operation. A well-designed cam switch should provide a clear and intuitive mechanism for switching between different modes or settings. This usability can significantly enhance productivity, allowing operators to make transitions swiftly and efficiently. Additionally, compatibility with various control panels and systems is vital. A versatile cam switch that integrates seamlessly into existing setups will save time and resources, making it a smart investment for any industry that relies on precise control systems.

Comparative Analysis: Cam Switch vs. Other Switching Devices

When considering switching devices for industrial applications, the cam switch stands out due to its durability and reliability. Unlike traditional rotary switches, cam switches offer a robust design that can handle high electrical loads and repeated use without compromising performance. According to a recent report by research firm MarketsandMarkets, the global market for cam switches is expected to grow significantly, driven by their ability to withstand harsh environments that other switching devices may not endure.

It's important to note that while alternatives such as toggle switches and push-button switches may offer simplicity, they often fall short in terms of longevity and load capacity. A study from the International Electrotechnical Commission indicates that cam switches can handle 50,000 to 100,000 operating cycles, far exceeding the life expectancy of most common switch types, which typically range from 10,000 to 20,000 cycles.

Tip: When selecting a cam switch, ensure it meets the specific electrical and mechanical specifications of your application to maximize efficiency and safety. Additionally, consider the installation environment; choosing a switch with appropriate IP (Ingress Protection) ratings can further enhance durability.

Overall, the comparative analysis between cam switches and other switching devices highlights the former's advantages in high-demand industrial settings, ensuring reliability and superior performance in critical operations.

How Cam Switches Enhance Safety and Efficiency in Industrial Applications

In today’s industrial landscape, the importance of cam switches cannot be overstated. According to a 2022 report by the International Electrotechnical Commission (IEC), approximately 30% of industrial accidents can be attributed to electrical failures due to inadequate switching devices. Cam switches, known for their robust design and versatility, play a crucial role in mitigating such risks. By providing precise control over various electrical circuits, they enhance the safety and reliability of industrial operations.

Moreover, cam switches significantly boost operational efficiency. A study conducted by the National Institute of Standards and Technology (NIST) highlights that industries employing advanced switching technology, such as cam switches, report up to a 15% increase in productivity. This improvement stems from their ability to facilitate quick transitions between different operational modes, reducing downtime and ensuring seamless workflow. As industries continue to focus on optimizing performance while ensuring safety, the adoption of cam switches emerges as a strategic move towards achieving these goals.

5 Reasons Why the Best Cam Switch Is Essential for Your Industrial Needs

This bar chart illustrates the key benefits of using cam switches in industrial applications, highlighting safety, efficiency, reliability, versatility, and ease of maintenance.

Top Brands for Cam Switches: A Comparison of Quality and Performance

When selecting a cam switch for industrial applications, the right brand can make a significant difference in both quality and performance. Leading brands in the market have established themselves through rigorous testing and innovative designs that cater to various industrial needs. For instance, brands like Siemens and Schneider Electric consistently deliver products that not only meet industry standards but also provide enhanced durability and reliability in adverse conditions. Their cam switches often feature superior materials and advanced engineering, ensuring they can withstand heavy-duty use.

On the other hand, brands such as ABB and Eaton are commended for their user-friendly designs and versatile product ranges. These manufacturers emphasize ease of installation and maintenance, making them popular among operators seeking efficiency. Their cam switches are engineered for high performance, offering smooth operation and longevity, essential for minimizing downtime in an industrial setting. By comparing these top brands, businesses can make informed decisions that align with their specific operational requirements, ultimately ensuring their systems remain efficient and safe.